swiss cnc machine programming

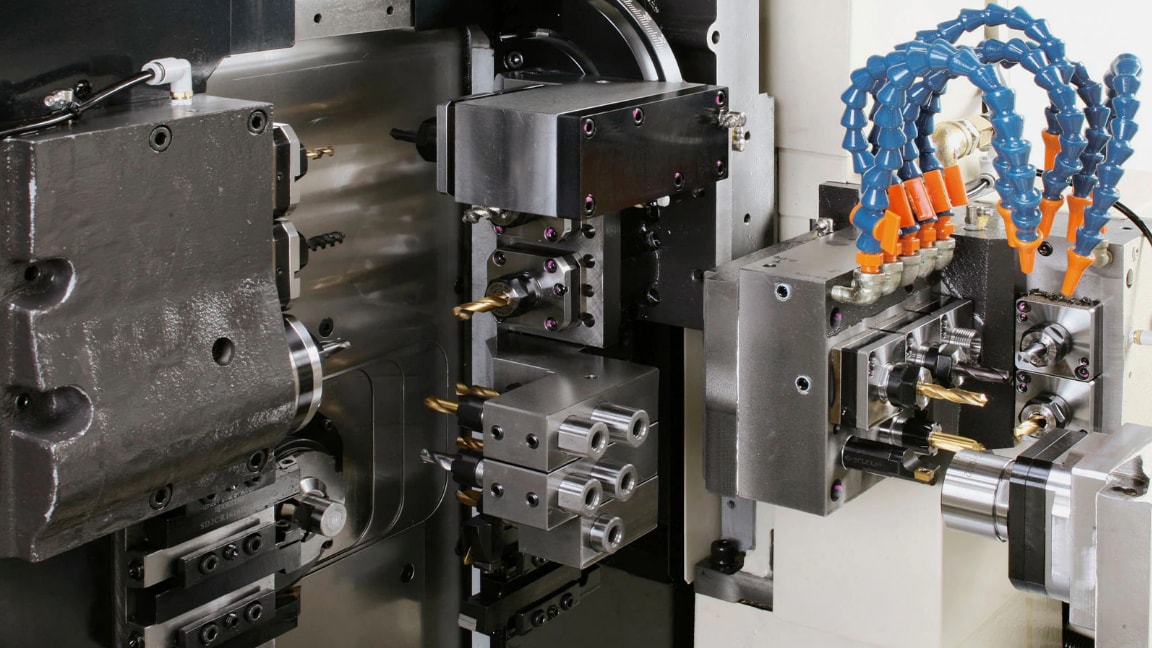

Understanding Swiss-Type Machining. The CAM system combines advanced multitasking programing functionality.

Cad Cam Swiss Machining Solutions Mastercam Products

This change affects the nature of programming offsets.

. In a nutshell their work instructs machines to produce parts. Grinding Machines Machining Centers Transfer Machines. While the revolving collet must be adjusted tighter to grip the bar when the sliding headstock moves in or out the guide bushing.

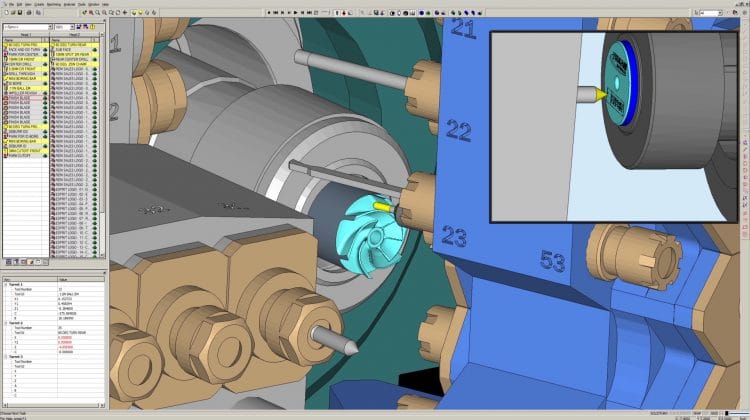

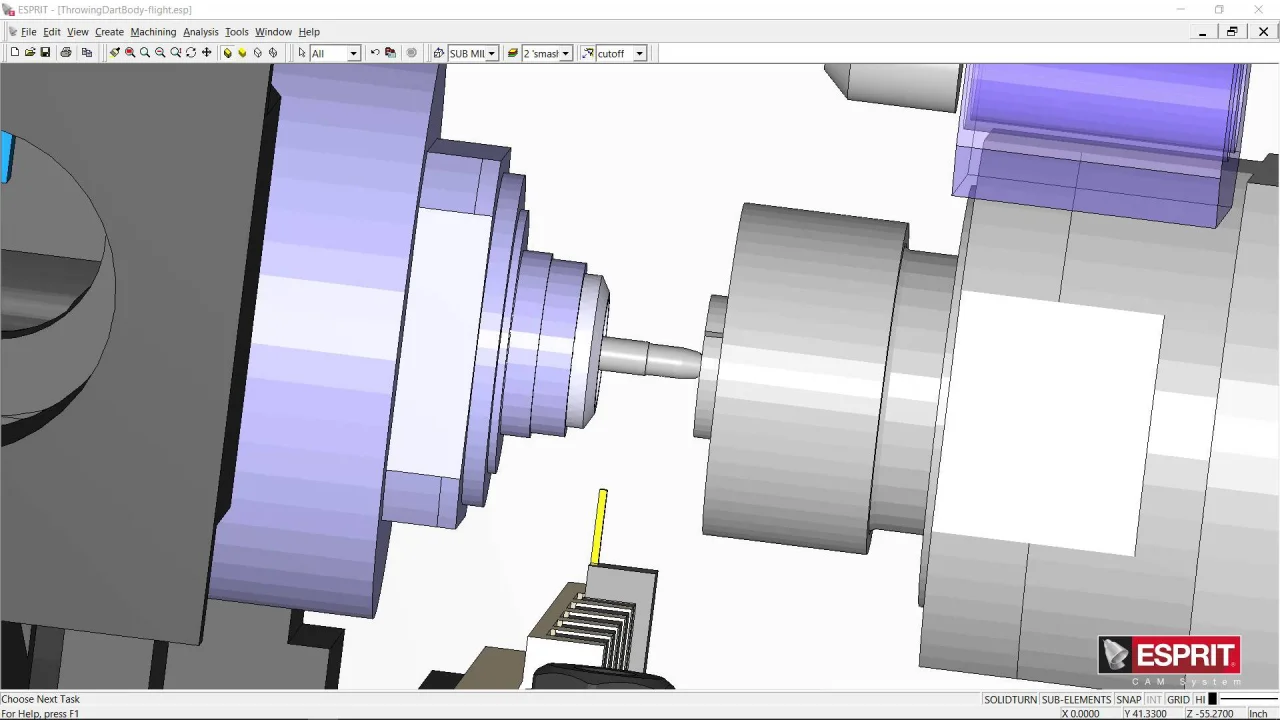

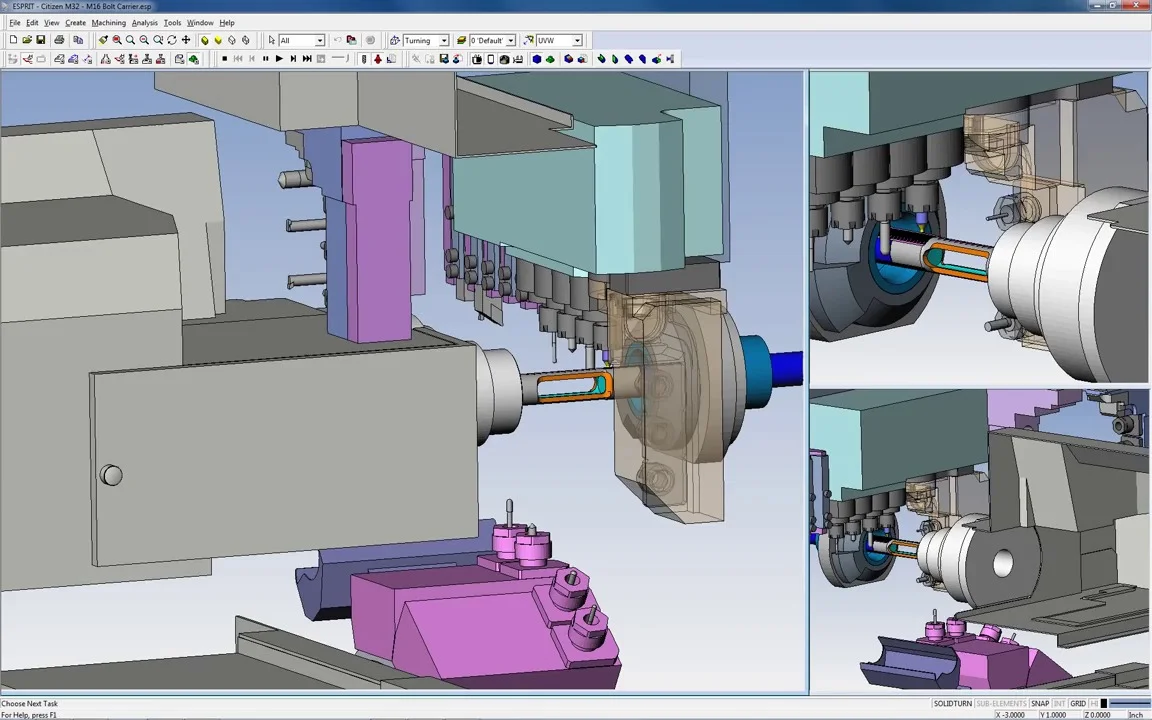

Specialized programming on CNC machines can be utilized to optimize processes simplify operations and combine families of parts. SolidCAM for multi-axis CNC Swiss type and multitasking turning centers provides a very efficient machine tool programming process generating optimal and safe Mill-Turn programs. Horizontal and Vertical Lathes.

G01 Linear interpolation. This comes with lots of exciting benefits including non-exposure to water-based coolants as is often the case with prune-like hands. Most programmers are ready to start making programs after a 3-day training course as opposed to weeks required for other solutions.

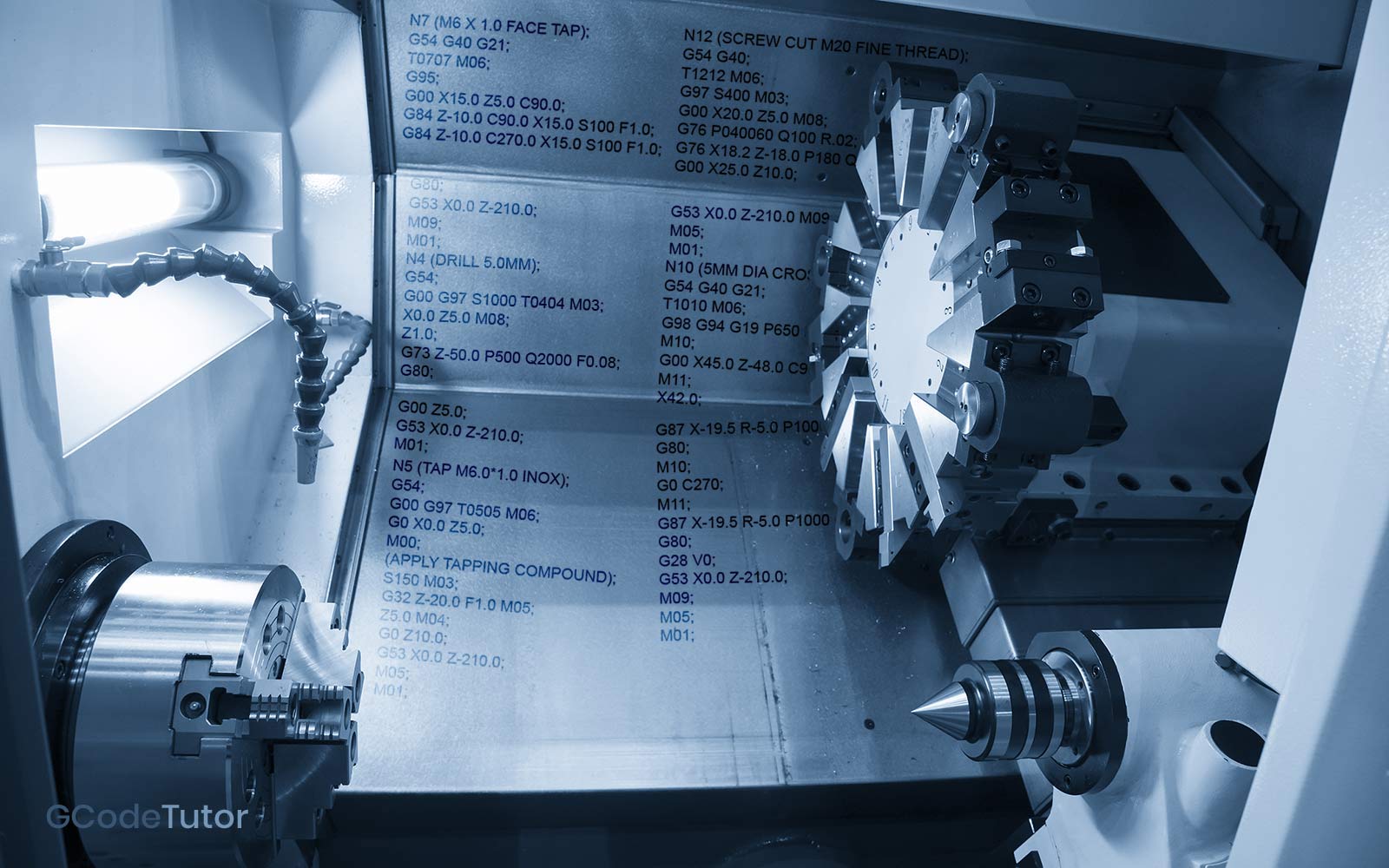

WinCNC was developed especially for Citizen users to be able to edit up to three programming systems at the same time. Check out the list of G-codes in CNC machining. Mastering lathe programming for Swiss-type machines will help you understand how to program turning or milling operations easily.

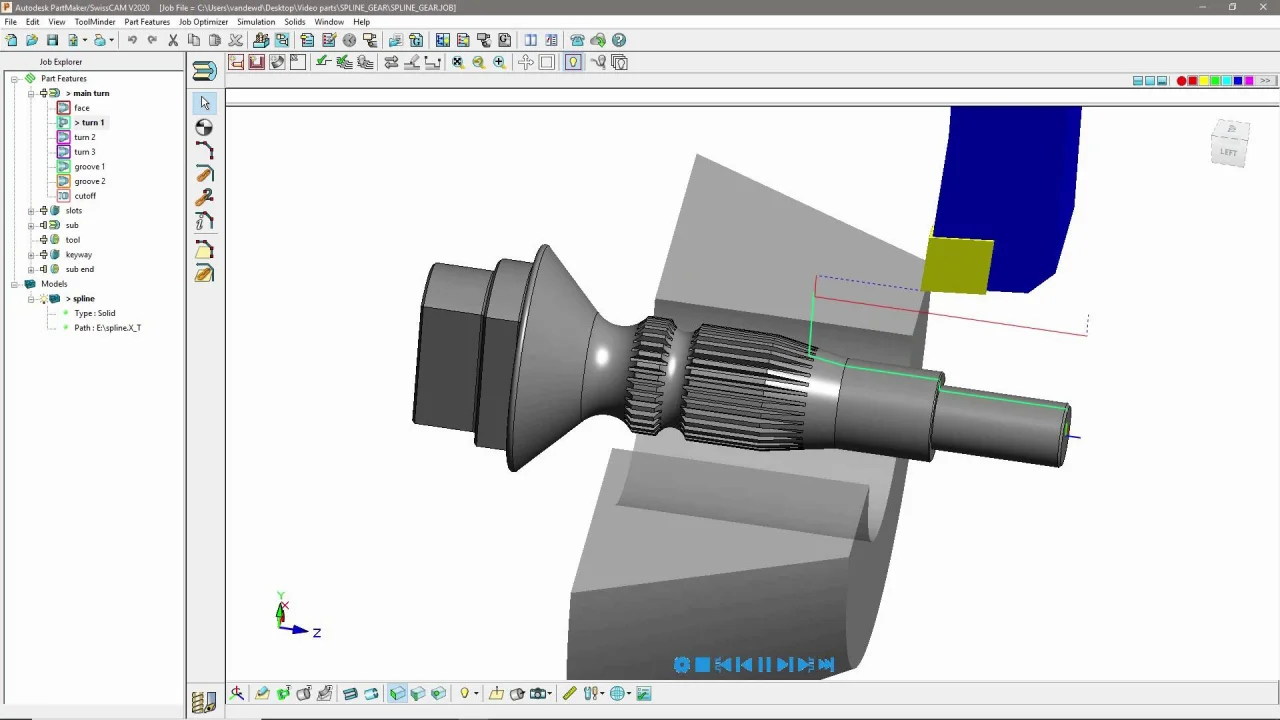

Blackstone Swiss Engineering is committed to providing technical support and engineering services to the Swiss machining industry in a cost effective way. These skilled workers must be proficient in both milling and turning operations and typically have a creative think outside the box mentality. PartMaker is the leader in Swiss programming because its purpose built for your complex machines and excels in these areas.

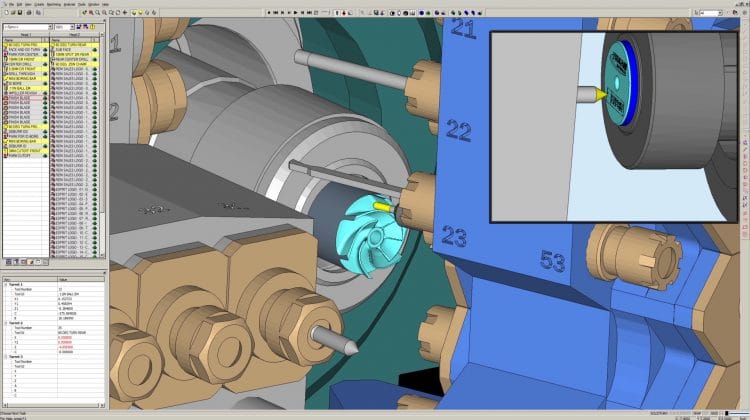

Machine simulation for Swiss lathes. By contracting with Blackstone machine shops get engineering support when they need it and keep engineering costs down when they dont. Easy to learn and use in a short amount of time.

G06 Parabolic interpolation. UGNX and CATIA systems have turning and milling complex CNC machining programming function mo. CITC partnered with a number of local Swiss users in the development of the program.

Here are a few points it communicates to its new Swiss operators. Verify and visualize your Swiss machining process with a digital twin of your specific lathe. For the newcomer to Swiss-type machining here is what the learning curve is like.

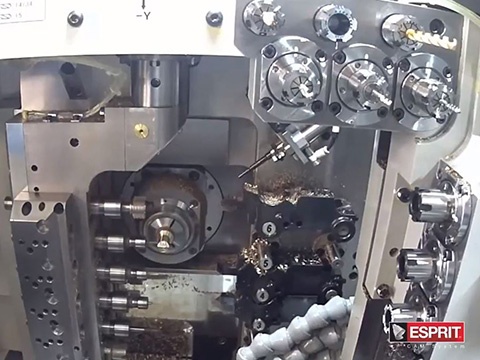

On Swiss CNC turning the Z-axis motion comes from the moving of the stock instead of the tool. CNC programming provides automation cost savings excellent machining quality flexibility. This adds significant value by reducing throughput times and labor because technicians dont need to transfer the work in progress to another.

The swiss type cnc lathe machine needs to complete the programming of various processing methods such as CNC turning multi-axis milling 32 positioning processing and drilling which is very difficult. By contrast nearly all of his companys Swiss machines come with free CAM programming software called Abile created by Tsugami. Additionally it also helps you understand how to verify them before placing them into the machine.

This is the perfect training for those employees or candidates transitioning to Swiss from conventional CNC or those who are new to CNC altogether but understand basic machining. Swiss Turn Solutions provides CNC programming for most equipment and controls specializing in Swiss CNC. A CNC Swiss-type lathe is capable of turning milling and threading to drop complex parts complete.

Rather than water many Swiss-type machines are now being designed to use oil. By Swiss Precision Machining Careers Machining December 10 2019. G08 Feed acceleration.

Also users experience greater freedom from odor-causing agents that promote. Most Swiss machines rely on third-party software that is flexible enough to output code for multiple machine types. Editor-in-Chief Modern Machine Shop.

In fact Swiss machines typically dont come with any software at all according to Briggs. Fusion 360 All-purpose CNC CAM Software. Once seen as a specialty machine tool the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines.

However running a Swiss-type isnt the same as running a traditional lathe. Capable of creating 2D and 3D CNC designs Fusion 360 also has a g-code editor and CNC simulator based on your chosen toolpaths. For turning longer length or drilling deeper holes the Swiss-type machine entails a plus offset while the conventional lathes require a minus offset.

G03 Circular interpolation counterclockwise. New Swiss CNC machines function with greater lubricity. Verify programs with confidence.

CreateEdit CNC programs that are unique to the Cincom ELMB Series machines with Mitsubishi Meldas and Fanuc controls. G02 Circular interpolation clockwise. Machine parts for you please EMAIL US.

Computer numerical control CNC programmers develop programs for precision CNC machines in order to cut and shape component parts for manufactured goods such as cars airplanes and medical devices. G00 Rapid positioning. On these advanced Mill-Turn and Swiss-type CNC machines.

Several patented features make a very. CNC Computer Numerical Control programming is growing in popularity in the manufacturing industry due to its many applications. Applying the right tools and technique to CNC part programming will let shops get the most out of their multitasking equipment.

With a huge market share and a favorite of many makers Fusion 360 is a great all-in-one CADCAM software for CNC. G05 High-precision contour control. The ease of use provided by automated machine tools has made it easier than ever to manufacture parts for different uses.

Here is why you need to master CNC Swiss lathe programming. CAM automation for CNC programmingnow available as part of Fusion 360 with FeatureCAM. The response to our 5-week CNC Swiss Machine OperationsSet-up class has exceeded expectations.

As you are creating a CNC program there are many tools to help you complete sections of the CNC code. Free for students and free trial then 495year. A swiss machinist is a skilled worker who specialized in operating Swiss CNC machines.

Know the difference between a headstock collet and a guide bushing. In contrast to a traditional CNC machine with 3 or 4 axes Swiss machines can equip up to 13 axes. Swiss machinists should have good working knowledge of multitasking machines and part-specific processes.

Programming Software Swiss Style Esprit By Dp Technology Simulation Cad Control

Wincnc Software Marubeni Citizen Cincom Inc

Learn More About Mastercam Swiss Machining Youtube

Swiss Type Machining Tuned For Swiss Type Cnc Turning Centers Programming Cycle Time Optimization And Full Machine And Process Simulation Espritcam

Programming Software Swiss Style Esprit By Dp Technology Simulation Cad Control

Swiss Type Machining Tuned For Swiss Type Cnc Turning Centers Programming Cycle Time Optimization And Full Machine And Process Simulation Espritcam

Autodesk Production Turning And Swiss Machining

Swiss Machining Made Simpler Worcon

What Is A Cnc Programmer Swiss Precision Machining

Open House At Milwaukee Area Technical College Gotomorris

Solidcam Cam Software Swiss Type Machining

Machining Multi Sided Part In One Setup On Swiss Style Cnc

How To Move Beyond Manual Programming With Customized Post Processors For Advanced Mill Turn And Swiss Type Event Details Modern Machine Shop

Cad Cam Swiss Machining Solutions Mastercam Products

Swiss Style Machines Simplified Sme Media

Autodesk Production Turning And Swiss Machining

Autodesk Production Turning And Swiss Machining

Program Your Citizen Multi Axis Swiss Style Turning Centers With Esprit Youtube